Decking Oil for Spotted Gum Timber decking

Now that your new Spotted Gum decking has been placed, you must decide which decking oil is best for Spotted Gum Decking. First off, I should mention that Spotted Gum is by far my preferred decking timber to deal with because of its characteristics that ensure no two boards will ever look the same.

You will have a choice of Blondes, Browns, and perhaps Pinks to exhibit based on the origin of your Spotted Gum. With the aforementioned in mind, I firmly believe that if you’re willing to oil Spotted Gum wood, it’s only fair to do so in a way that highlights its features. You should definitely run with a translucent oil to do this. Now, when I say transparent oil, I don’t mean to tell you to go out and purchase some Clear because you will be lucky to get three months out of your oil.

If you are from Australia, you must use oil that contains some colour when oiling Spotted Gum decking because your timber will be exposed to the elements due to our severe UV rays and various weather conditions.

Here is a picture of a deck with a mixture of Yellow Box and Spotted Gum timbers that have been treated with our favourite oil.

This is a good example of showing the lightest I would ever recommend going with Spotted Gum using a oil.

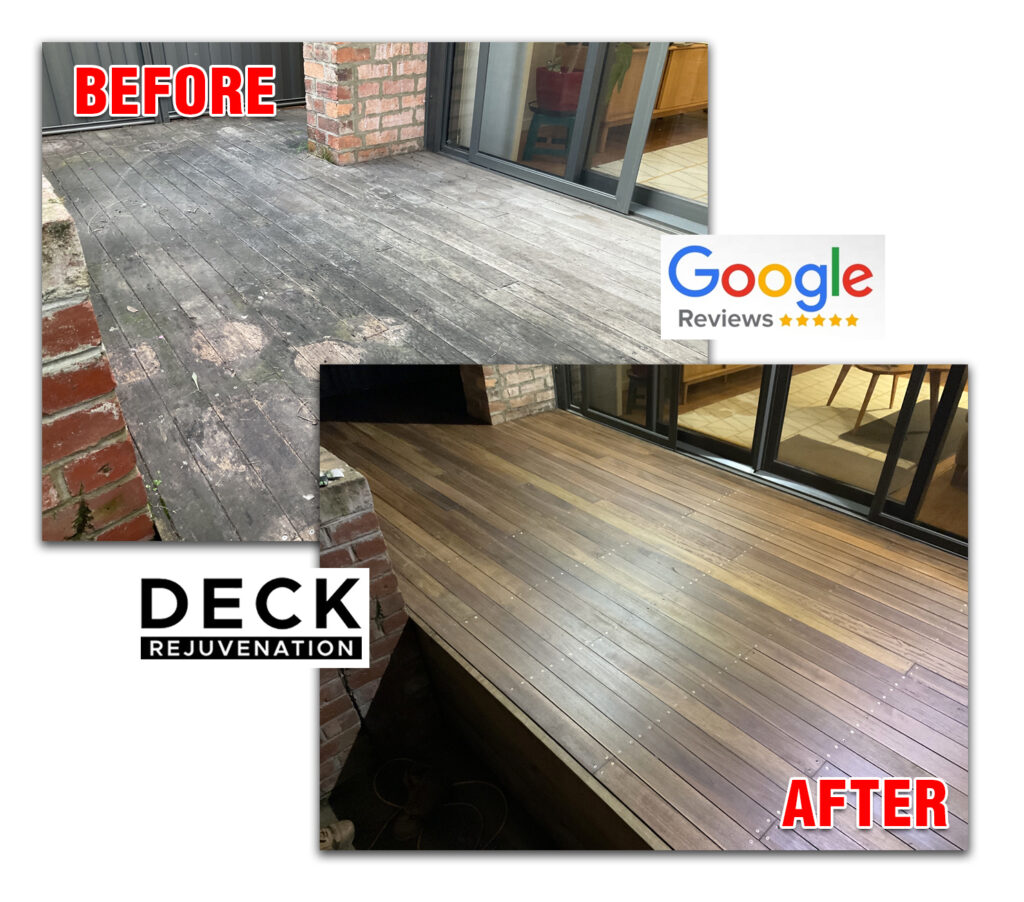

Here is a old Spotted Gum deck we restored and finish a Oak finish. (my fav these days as of 2021)

Want someone to handle it properly for you?

No guesswork. No shortcuts. No early failures.

📞 Book now: 1300 363 478

Or jump to our home page and request a free quote — we’re happy to help.

The deck pictured above is a Spotted Gum deck we restored back to near-new condition. This wasn’t a simple clean and recoat — it required five separate sanding passes and two different chemical processes to strip back years of UV damage and moisture-related failure before we could expose healthy timber again.

If your Spotted Gum deck is starting to grey, cup, or lose consistency, it’s worth addressing early.

Small issues are far easier — and far cheaper — to fix before they turn into full restorations like the one shown here.

📞 1300 363 478 — we’re happy to take a look and point you in the right direction.

Australian conditions demand oil with some colour when oiling Spotted Gum decking. Our UV exposure is harsh, and without pigment, the timber is left vulnerable to rapid deterioration from sun and weather.

Spotted Gum decking has many benefits, but it also has limitations that people need to understand. It isn’t the most forgiving timber. With its knots and natural grain variation, it moves more than many expect. If moisture becomes trapped — through poor detailing, restricted airflow, or incorrect preparation — the timber expands and contracts unevenly. Over time, this leads to cracking, warping, and premature failure.

If you’re currently planning a deck build and comparing the cost of Spotted Gum decking per square metre to Merbau or similar timbers, it’s important to understand that Spotted Gum is more expensive — and mistakes are more costly. When managed properly, it will outlast and outperform many alternatives. When managed poorly, it often ends up needing restoration far earlier than expected.

The guidance below is based on real-world failures we see regularly, as well as builds that have stood the test of time.

👉 14 Practical ways to extend the life of your Spotted Gum deck by 15+ years

- Tip 1: Allow Spotted Gum to release tannins before sealing

Before applying any protective coating for the first time, Spotted Gum needs to release some of its natural tannins. If this step is rushed or skipped, those tannins can interfere with how the oil bonds to the timber and lead to uneven results.

There are two ways to manage this:

-

Natural weathering — allowing the deck to sit exposed for 6–8 weeks

-

Chemical preparation — using a controlled treatment to draw tannins out more evenly

While natural weathering does work, it often leaves the boards weathering inconsistently, especially in areas with mixed sun and shade. For this reason, we generally prefer to chemically initiate the process, as it produces a more even, predictable surface before oiling.

Getting this step right sets the foundation for everything that follows.

-

- Tip 2: Cleaning requirements depend on whether the timber is new or previously coated

For new, uncoated Spotted Gum, the deck should be thoroughly cleaned using an acid-based wash and given a proper scrub before oiling. Most deck wash products are oxalic-acid based and are designed to clean the timber and prepare it for its first coating.

It’s essential to follow the product instructions carefully and ensure the acid is fully rinsed and neutralised. Any acid residue left in the timber can interfere with how the oil bonds and may cause premature coating failure.

If the deck has already been coated and the existing finish is still intact, an acid wash is usually unnecessary. In these cases, a mild, pH-neutral cleaner is sufficient to remove surface grime before recoating. Products such as pH-neutral floor cleaners or car wash solutions work well, provided the coating has not broken down.

The key distinction is this:

-

New timber → acid wash and proper preparation

-

Previously coated, intact surface → mild degreaser only

Using stronger cleaners on an intact coating can do more harm than good.

-

- Tip 3: On some new decks, you might see black discoloration from metal that was chopped during the construction of a balustrade and could have seeped into the wood. Don’t be hesitant to give these areas a second or a third acid wash, keeping the same water/acid combination as the remainder of the Spotted Gum Decking. *This also works great from bleaching pot marks.*

- Tip 4: Your Spotted Gum Decking Timbers has now been weathered, the tannin has been removed, it has been cleaned, dried, and is prepared for decking oil. Thus, the famous question arrives, “What is the finest decking oil for spotted gum decking timbers?” The finest oil you might currently afford is the answer to this. Plus don’t commit the mistake of purchasing cheap oil from your neighborhood hardware shop because you used a showcase wood for your decking build. You will be extremely disappointed. The ideal Decking Oil for Spotted Gum Timber Decking mixture for Spotted Gum is two coatings of oil with a somewhat reddish tint since it highlights the pinks, followed by a matte clear coat.

One benefit of a matte finish is because it can conceal blemishes from regular use. If you choose a high sheen finish, this will create a small line which will be visible as light diffracted off the coating every time the children toss bikes down or even a chair is shifted. The Australian Spotted Gum Timber Decking oil market is mostly controlled by a corporation that holds a monopoly, controls 80% of the brands available, and has, unsurprisingly, been acquired by foreign parties.

- Tip 5: Don’t get distracted by “Good / Better / Best” labels

Most decking oil brands offer a Good, Better, Best range. The real difference between them isn’t branding — it’s the quality of the UV protection and pigments inside the oil.

Cheaper oils rely on thicker, cloudier coatings to give the illusion of protection. They use lower-grade UV inhibitors, which break down faster and leave the timber exposed sooner. The result is a deck that fades, greys, or fails well before it should.

Higher-quality oils use better UV inhibitors and cleaner pigments, allowing the timber’s natural character to show through while still providing proper protection. They also apply more evenly, foam less, and age far more predictably.

With decking oils, price usually reflects performance. On a premium timber like Spotted Gum, cutting corners here almost always costs more later.

- Tip 6: Make careful you follow the manufacturer’s instructions on the container and give each coat ample time to dry. If at all possible, take pictures of the project after each coating so that, in the event that they issue a warranty on the work, you have the documentation you need to defend yourself.

- Tip 7: Allow time between coats — and re-clean if needed

Ideally, oiling a deck should be done over consecutive days so each coat goes on a clean surface.

If you only have time to apply one coat and can’t return for a week or more, the deck will collect dust, pollen, and airborne grime in the meantime. Before applying the second coat, the surface must be cleaned again — otherwise you’re sealing contaminants into the timber.

Skipping this step leads to patchy finishes and early coating failure.

- Tip 8: Temperature matters more than people realise

Avoid oiling Spotted Gum decking in extreme temperatures. When it’s too hot, the oil flashes off too quickly, which almost always leads to lap marks and an uneven finish. When it’s too cold, the oil struggles to penetrate and cure properly.

As a general rule, don’t oil your deck when temperatures are below 10°C or above 30°C.

The best conditions are a mild, overcast day between 15°C and 25°C. In that window, the oil is easier to work with, spreads evenly, and cures the way it’s supposed to — without stress or surprises.

- Tip 9: Keep furniture off the deck while the oil fully cures

After oiling, your Spotted Gum deck needs time to cure properly. While the surface may feel dry to the touch within a day or two, the coating is still cross-linking and hardening beneath the surface.

For the first seven days, keep all furniture, pots, mats, and heavy foot traffic off the deck. During this period, the coating is at its most vulnerable. Dragging chairs, placing pot feet, or sliding furniture can scratch or disturb the finish before it has reached full hardness.

Damage done at this stage doesn’t just affect appearance — it weakens the coating long-term and shortens the time before the deck needs re-oiling.

Giving the oil a full week to cure allows it to harden properly, making the surface far more scratch-resistant and durable.

- Tip 10: Ventilation is critical with Spotted Gum

Spotted Gum is a dense timber, but it doesn’t tolerate being left damp. If moisture is allowed to sit around or beneath the deck, the timber will move more than it should, leading to cupping, cracking, and long-term issues.

Good ventilation is one of the most important — and most overlooked — factors in a Spotted Gum deck. If airflow is restricted, moisture has nowhere to escape.

Where possible, ventilation should be improved. This may mean installing vents, opening up side panels, or creating airflow pathways beneath the deck. Improving ventilation early can prevent a long list of problems later.

-

Tip 11: Winter is for drying, not storage

Remove:

-

Mats

-

Pots

-

Furniture

Let the deck breathe between rain events.

-

- Tip 12: Correct board spacing is non-negotiable with Spotted Gum

When Spotted Gum decking is laid, boards must be spaced at least 5–6mm apart. This spacing isn’t cosmetic — it’s essential for drainage, airflow, and allowing the timber to move naturally.

Spotted Gum expands and contracts with changes in moisture and temperature. If boards are laid too tightly, there’s nowhere for that movement to go. Water becomes trapped between boards, airflow is restricted, and the timber stays damp for longer than it should.

Over time, inadequate spacing leads to:

-

Cupping and warping

-

Splitting along the grain

-

Accelerated coating failure

-

Premature need for sanding and restoration

We regularly see decks that look fine when first built, only to fail within a few years because board spacing was too tight from day one. Once the deck is down, spacing issues are difficult and expensive to correct.

Getting the spacing right at install is one of the simplest ways to extend the life of a Spotted Gum deck.

-

Below is a short video condition report for a client in Melbourne showing a new Spotted Gum deck build. In this instance I rejected the build and instructed the client to have the builder remove and reinstate half the deck due to poor spacing’s. If board spacings are not correct and the area has poor airflow the build is destined to fail.

- Tip 13: Make sure the wood never comes into touch with grass or soil boundaries because this will cause wood to deteriorate quickly.

(Below is a new Spotted Gum deck is the front trim having contact with the ground – this timber will cause the step to start rotting out in under 12 months.)

Here is a prime example of a side trim causing the sub floor to rott out on a deck thats only a few years old

- Tip 14: Do not believe the manufacturer’s statements on the cans! The unfortunate fact is that you chose lovely, feature-rich racing car wood… There is however a cost involved, and it is not just referring to the initial build. If the Decking Oil for Spotted Gum Timber Decking is exposed to direct sunlight or other irregular exposure, it must be given a service coating of oil every six months on schedule. If you will not have side-on exposure, it’s safe to run in undercover places every 12 months.

Here is a photo of a Spotted Gum deck we sanded/sealed using our favorite combination of oils. This deck had previously been coated with one of Bunnings top-selling brands which resulted in early life failure.

***Personal note – thanks for all the lovely phone calls I’ve had with people calling to express a thank-you from different states around Australia 🙂 puts a smile on a my dial. If you honor the above golden rules for Spotted Gum decking, I can assure you it will last the test of time. Kind Regards, Ben J – Deck Rejuvenation Pty Ltd***

Want someone to look after your Spotted Gum deck for you?

Book now 1300 363 478

We are happy to help!

Hear what some of our recent clients have to say!

Or Submit your details on our home page Here to Arrange a free Quote.