That thick, stubborn coating on your deck feels impossible to shift. You’ve considered a regular sander, but you know it means weeks of back-breaking work for a patchy result. So, the idea of sandblasting a deck sounds like the perfect answer—a powerful, fast way to strip it all back to bare timber.

It’s a tempting shortcut, and many operators are happy to take your money for it. But here’s the honest truth they won’t tell you: sandblasting is a high-risk gamble for timber. It’s an aggressive, uncontrolled process that blasts away the soft grain, leaving your deck boards gouged, splintered, and permanently damaged. We’ve been called in to rectify these costly mistakes across Melbourne for over 17 years.

Before you make a decision that could ruin your deck, read on. We’ll show you the real-world damage sandblasting causes and explain why a professional, meticulous sanding process is the only way to achieve a genuinely superior, long-lasting finish that protects your investment.

What is Deck Sandblasting and Why Do People Consider It?

Your deck is a mess. Years of thick, peeling paint or a stubborn, failed stain have left it looking tired and neglected. You’ve tried chemical strippers and hours of sanding, but nothing seems to cut through the layers. It’s a frustrating and common problem, and it’s usually at this point that homeowners start searching for a more powerful solution.

Sandblasting is a term often used for the industrial process of abrasive blasting. The core principle is simple: propel a stream of abrasive material at a surface under high pressure to strip it clean. While sand was the original medium, modern methods use a variety of materials depending on the job, including:

- Crushed glass or glass beads: Aggressive and effective for tough coatings.

- Soda bicarbonate: A softer, water-soluble option.

- Walnut shells or corn cobs: Organic, biodegradable, and gentler abrasives.

The appeal is obvious: speed and power. When you’re facing a seemingly impossible stripping job, the idea of blasting it all away in a fraction of the time is tempting. This is a method borrowed from heavy industry, where it’s used to strip rust from steel and clean concrete. The question is, does that power translate well to the soft timbers of a residential deck?

The DIY Dilemma: When a Floor Sander Isn’t Enough

Many homeowners find themselves considering sandblasting a deck out of sheer desperation. A standard floor sander, while excellent for interior floors, often struggles with the realities of an old deck. Multiple layers of thick paint or gummy, oil-based stains can quickly clog expensive sandpaper, turning a weekend project into a costly, labour-intensive nightmare. Sandblasting appears to be the ‘nuclear option’—a way to bypass the frustration and get straight to bare timber.

Sandblasting vs. Soda Blasting vs. Pressure Washing

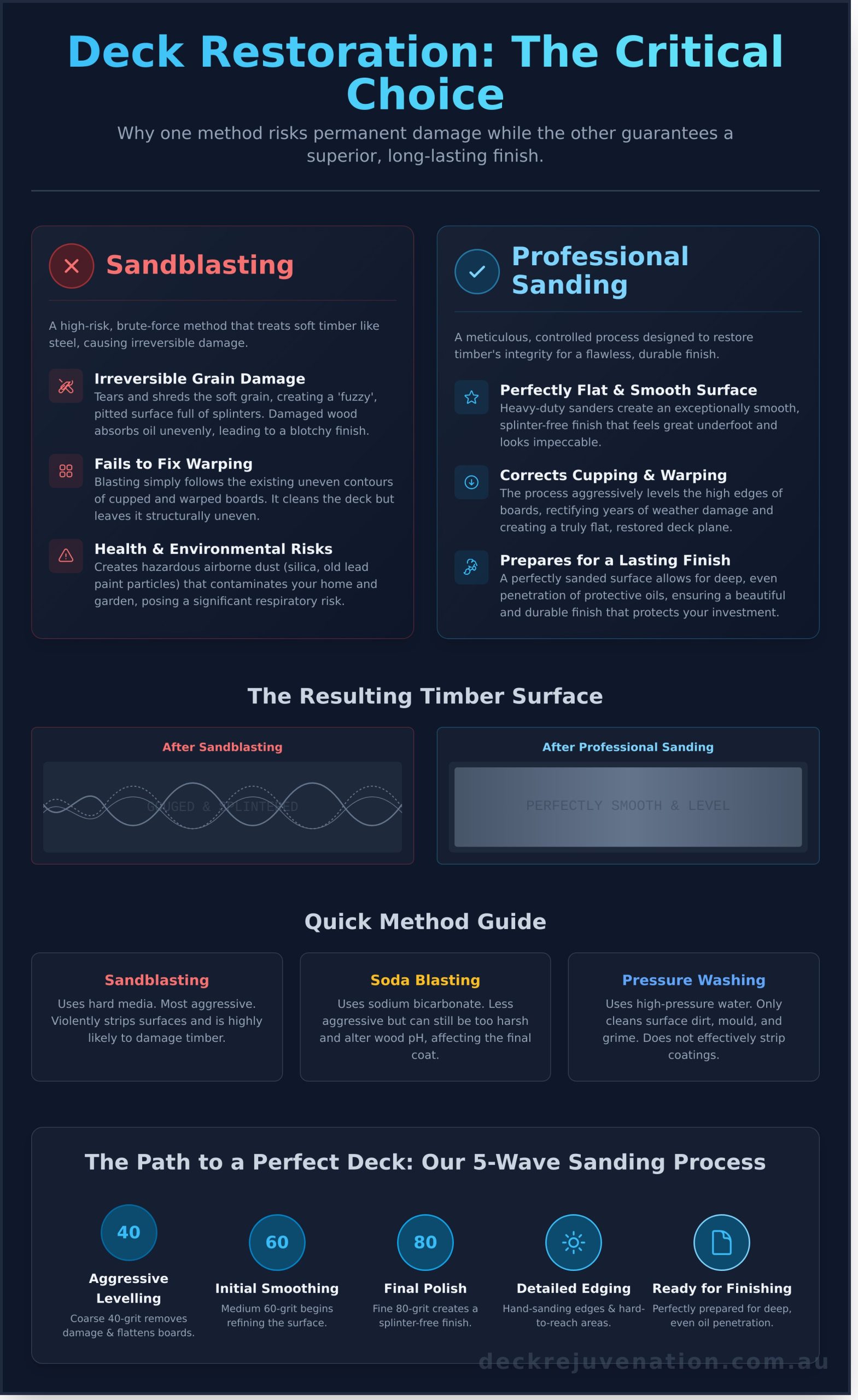

It’s crucial to understand the difference between these methods, as they are often confused. Here’s the honest, no-nonsense breakdown:

- Sandblasting: The most aggressive option. It uses hard media to violently strip the surface. While effective on metal, it has an extremely high risk of permanently damaging, splintering, and gouging soft deck timbers like pine or even tougher hardwoods.

- Soda Blasting: A less aggressive alternative that uses sodium bicarbonate. While softer, it can still be too harsh for many types of wood and can alter the pH of the timber, potentially affecting how a new coating is absorbed.

- Pressure Washing: Uses high-pressure water, sometimes with a cleaning solution. It is excellent for removing dirt, grime, and mould but lacks the force to strip well-adhered paints and stains. It cleans; it does not strip.

The Major Risks: Why Sandblasting Can Ruin Your Timber Deck

Some contractors treat timber like it’s a steel girder or a concrete slab. They believe you can simply blast away an old coating and be left with a clean slate. This is a fundamental misunderstanding of wood. Timber is a soft, fibrous material, and hitting it with high-pressure abrasives is a recipe for disaster that causes permanent, irreversible damage.

Irreversible Damage to the Wood Grain

The primary issue with sandblasting a deck is the catastrophic damage it inflicts on the wood itself. The aggressive force doesn’t just strip the coating; it tears and shreds the soft grain of the timber, creating a permanently ‘fuzzy’ and pitted surface. This raised grain is not only a splinter hazard for bare feet, but it also ruins any chance of a quality finish. Damaged, porous wood soaks up oil unevenly, resulting in a blotchy, unprofessional look that can never be rectified.

It Doesn’t Solve the Real Problems: Cupping and Warping

A genuine deck restoration isn’t just about colour; it’s about rectifying structural imperfections like cupped and warped boards. Sandblasting does nothing to fix this. It simply follows the existing uneven contours, blasting the high spots and low spots equally. You are left with a clean but still warped and uneven deck. A truly restored deck must be flat, which is something only meticulous, professional sanding can achieve by levelling the high edges of the boards.

Health and Environmental Hazards

Beyond the damage to your timber, the process itself is messy and hazardous. The abrasive media—often containing fine silica dust—and particles of old coating become airborne. This creates a significant respiratory risk, especially if you’re dealing with older decks that may have been treated with lead-based paints. The US Occupational Safety and Health Administration details many of these risks in its guide on the Hazards of Abrasive Blasting Materials. Containing this fine dust is nearly impossible; it will find its way into your garden, pool, and home, creating a cleanup nightmare that can last for weeks.

Professional Deck Sanding: The Superior Alternative

While sandblasting a deck is often pitched as a quick fix, it’s a brute-force method that fundamentally misunderstands timber. A true craftsman knows that preparing a deck isn’t about aggressive stripping; it’s about meticulous resurfacing. This is where professional sanding stands apart. It’s a controlled, precise process designed to restore, not just destroy. The high-pressure impact of blasting can permanently damage the timber grain and poses significant safety issues, as detailed in reports on the OSHA health risks of abrasive blasting due to airborne particles. We take a different approach. Our process involves up to ‘5 waves of sanding’—a methodical system that ensures your deck is not just clean, but perfectly prepared for a finish that lasts.

Achieving a Perfectly Flat and Smooth Surface

Years of weather can leave your deck with cupped, warped, and uneven boards. Our heavy-duty floor sanders are designed to rectify these issues, not just skim the surface. We start with a coarse 40-grit paper to aggressively level the entire deck, removing the damaged top layer and creating a perfectly flat plane. We then progress through finer grits, finishing with an 80-grit to produce a surface that is exceptionally smooth, splinter-free, and ready to feel great underfoot.

Preparing Timber for Deep Oil Penetration

A long-lasting finish depends entirely on how well the oil penetrates the timber. Our multi-stage sanding process opens up the wood’s pores, creating a thirsty surface that readily absorbs premium oils. In contrast, the high-velocity impact from blasting often hammers the timber grain shut, preventing deep absorption. This leads to a finish that sits on the surface and fails prematurely. Better oil penetration means genuine, long-term protection from the harsh Australian sun and rain. See our 9-step process for a flawless finish.

Precision Work Around Edges and Details

A deck isn’t just the main boards. It’s the edges, the corners, and the areas around posts. The imprecise spray pattern of a sandblaster makes it impossible to work neatly in these areas without causing collateral damage. We use specialised edgers and detail sanders to ensure every single inch of your deck is sanded to the same high standard. It’s this commitment to precision that guarantees a uniform, professional result. No shortcuts, no corners left untouched.

Sandblasting vs. Sanding: A Head-to-Head Comparison

When it comes to stripping your deck back to bare timber, the method chosen is the single most important factor for the final result. While the idea of quickly sandblasting a deck might seem efficient, it introduces serious problems that a professional sanding process is designed to solve. Here’s a direct comparison to make the right choice for your home obvious.

Verdict on Finish Quality and Flatness

Sandblasting is a blunt instrument. It aggressively strips coatings but leaves behind a rough, pitted, and uneven surface. It gouges the soft grain of the timber, creating a texture that feels coarse underfoot. Crucially, it cannot rectify cupped or warped boards, leaving your deck uneven. Professional sanding, by contrast, is a meticulous process that levels the timber, rectifies cupping, and creates a perfectly flat, silky-smooth surface ready for oiling.

Winner: Professional Sanding, for a superior look and feel.

Verdict on Timber Health and Longevity

The violent impact of sandblasting shreds the surface fibres of the wood, leaving it fuzzy and damaged. This compromised surface prevents deck oils from absorbing deeply and evenly, leading to a patchy finish and drastically reduced protection. This damage invites moisture ingress and splinters. A proper sanding process opens the wood grain cleanly, allowing for maximum penetration of premium oils. This ensures the timber is protected from within, guaranteeing a healthier, longer-lasting deck.

Winner: Professional Sanding, for a healthier, longer-lasting deck.

Verdict on Control and Mess

The lack of control is a major drawback of sandblasting. The high-pressure spray of abrasive media can easily etch glass windows, dent downpipes, and damage surrounding garden beds. It also creates a huge amount of fine dust that spreads everywhere. Professional deck sanding is a highly controlled process. Our specialised equipment is fitted with powerful dust extraction systems that capture the vast majority of dust, ensuring a much cleaner, more contained, and neighbour-friendly job.

Winner: Professional Sanding, for a cleaner, more controlled process.

The conclusion is clear. While sandblasting can remove an old coating, it fails on every measure of quality, longevity, and care. It’s a shortcut that ultimately costs you more in the long run through poor results and potential damage. For a genuine professional finish that protects your investment and looks incredible for years to come, professional sanding is the only correct choice. No shortcuts, just results.

The Final Verdict: Choose Precision Over Power for Your Deck

The honest truth is that when it comes to sandblasting a deck, the risks of splintering, gouging, and permanent damage far outweigh any perceived benefits. This aggressive method strips away the soft grain of the timber, leaving an uneven and weakened surface. The superior alternative is professional deck sanding—a precise, controlled process that rectifies imperfections and prepares your timber for a finish that truly protects and enhances its natural beauty.

Don’t gamble with your valuable outdoor asset. As a Melbourne family business with over 17 years’ experience, we pride ourselves on honest advice and our meticulous 5-wave sanding process. We take no shortcuts. For a professional opinion you can trust, get a free, honest assessment for your deck restoration. Let’s give your deck the expert care it deserves and ensure it remains a beautiful feature of your home for years to come.

Frequently Asked Questions About Sandblasting a Deck

Can you use a sandblaster to remove old paint from a deck?

Technically, yes, but it is a method we strongly advise against for any timber deck. Sandblasting is far too aggressive for wood. It shreds the soft grain, leaving a furry, splintered, and uneven surface that is impossible to coat properly. This approach causes irreversible damage and is a shortcut that ultimately leads to a more expensive repair job. Professional sanding is the only way to correctly prepare the timber for a new finish.

Is soda blasting safer than sandblasting for a timber deck?

While soda blasting is less aggressive than using sand, it is still the wrong tool for the job. The primary issue is that soda media can alter the pH balance of the timber. This chemical change interferes with the ability of premium oils and stains to penetrate and adhere correctly, leading to a patchy finish and premature coating failure. You are simply trading one problem for another. Proper mechanical sanding avoids these chemical complications entirely.

What is the cost of sandblasting a deck compared to professional sanding?

Many assume blasting is cheaper, but it’s often more expensive and delivers a disastrous result. In Australia, expect to pay A$50-A$80 per square metre for abrasive blasting due to the risk and setup. In contrast, our meticulous sanding process, which properly levels and prepares your deck, typically costs A$40-A$60 per square metre. The true cost of sandblasting a deck is paying a professional like us to come and fix the damage afterwards.

How do you fix a deck that has been damaged by sandblasting?

Fixing a sandblasted deck requires an aggressive and meticulous recovery process. We must use heavy-duty sanding equipment to grind down past the damaged, furry top layer of the timber to reach a solid, smooth surface. This often means removing more wood than in a standard restoration. It is a labour-intensive job of levelling the boards and restoring a viable surface that will accept a new protective coating. It’s a salvage operation, not a simple recoat.

Why can’t I just use a high-pressure washer to strip my deck?

Using a high-pressure washer to strip a deck is a common and costly mistake. The intense pressure forces water deep into the timber grain, causing it to swell, splinter, and fuzz up. This creates a damaged, porous surface that absorbs stain unevenly and promotes mould growth. A pressure washer is a cleaning tool, not a stripping tool. It’s a shortcut that guarantees a poor, short-lived finish that we are often called in to rectify.

What is the best way to strip a deck with multiple layers of old stain?

The only correct and professional method to remove multiple, failed layers of stain is with mechanical sanding. This process physically removes the old coatings and the top layer of weathered timber, exposing a fresh, clean surface. Critically, it also allows us to level cupped or uneven boards. This creates the perfect foundation for new, premium coatings to penetrate deeply and evenly, ensuring genuine, long-lasting protection for your investment.

Leave a Reply